|

|

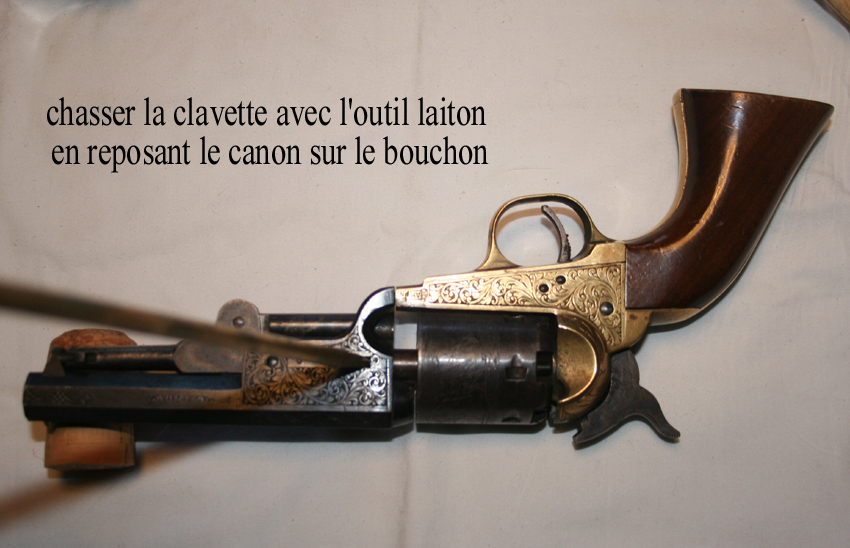

If the

key resists when fully inserted on the right side, continue to

chase it with a small flattened brass rod, no steel you would

irrevocably mark the tan and the steel of the barrel console.

D-Once

the key has been removed, unlock the loading lever (34) and place

the end of the drum (33) between two barrel chambers.

If you are afraid of marking the barrel by this maneuver, place

a wooden or cardboard tongue between the drum and the drum, and

leverage by pressure or small blows from the mallet to release

the barrel assembly (26) from its tenons. Positioning (14)

E-Remove the barrel (24)

F-Chimneys of the barrel must

be dismantled regularly and oiled at reassembly not necessarily

with each shooting session but at least monthly if one pulls often.

This is to avoid an oxidation of the pitch of the

chimneys which would definitely block the chimneys, that nevertheless

it will be necessary to change these ones being used with the

repeated blows.

The chimneys are only dismantled

with the appropriate key, Of this one, do not try other tools

that could only deteriorate them.

G- Sometimes

it is necessary to disassemble the drum to remove the powder residue.

Unscrew and remove the axle of the loading lever (32) Remove the

drum from its housing. If necessary, unscrew the axis of the drum

for cleaning and oiling.

H- Rebuild the dog which

releases part of the tension of the dog spring.

I-

Unscrew and remove the heel screw (22a)

J- Unscrew

and remove the 2 high handle screws (17)

K- The

handle And the armature detaches, separating the handle frame

(16) from the handle (18). It is not necessary to dismantle the

hammer spring (19) completely for the convenience of disassembling

the under-guard (21), the screw of the hammer spring (20) may

be partially desiccated.

L- Unscrew and remove the

front under-guard screw (23)

M- Unscrew and remove the 2 backscrews (22), the under-guard comes

off as soon as the hammer spring is released.

Then dismantle the mechanism.

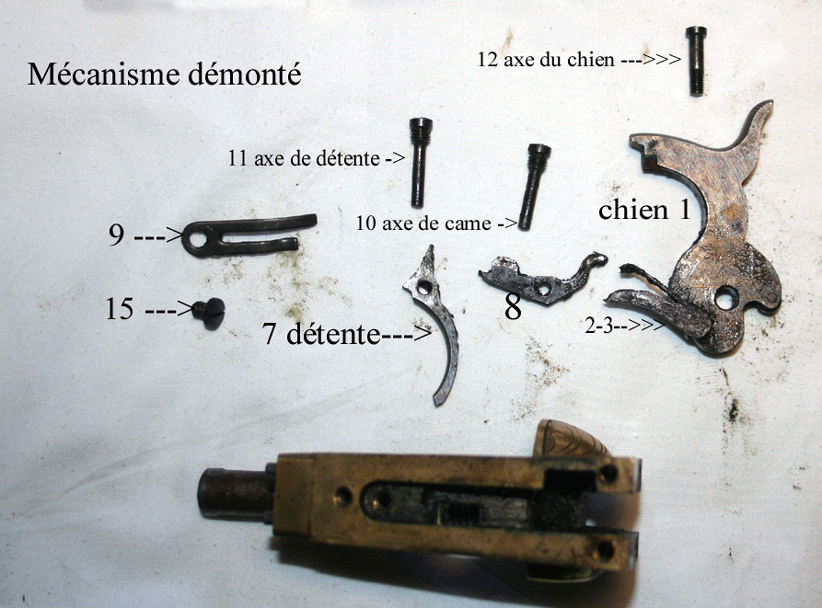

N- Unscrew and remove the retaining spring and

trigger spring screw (15)

O- Remove the spring

(9)

P- Unscrew and remove the expansion pin (11)

Q- Remove the trigger (7)

R- Unscrew

and remove the retaining cam shaft (10) and remove the retainer.

8).

S- Unscrew and remove the shaft from the hammer

(12) The hammer can now be removed from the underside of the frame

by driving the lifting finger (2) and its spring (3) together.

These two parts must not be separated because They are blocked

from factory.

With the mechanism completely

removed, thoroughly clean each piece to be removed from any black

powder residue. Oil each piece when reassembling.

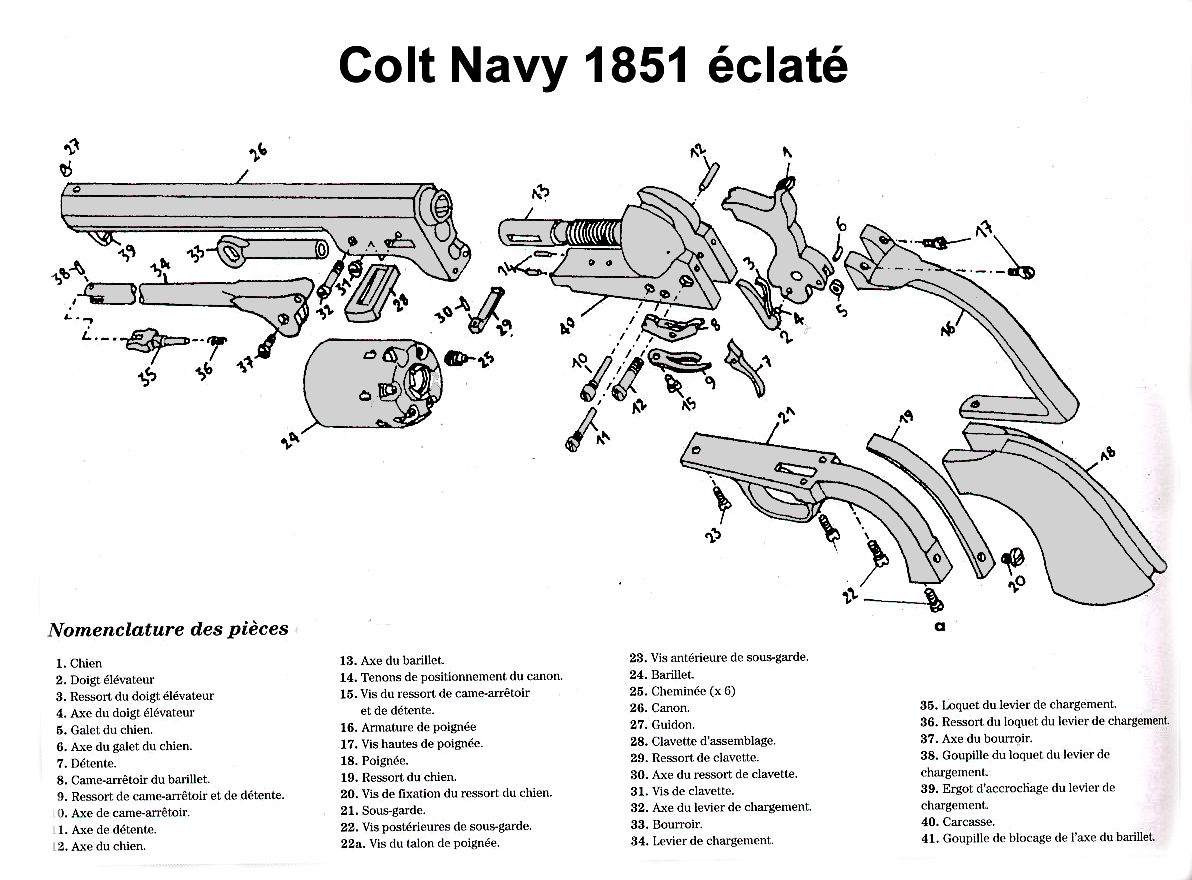

It is not necessary or even advised not to touch the barrel shaft

which has been fixed and adjusted by the manufacturer, do not

disassemble the handlebars, do not touch the axles (4) (6) (30),

the pins (14 and 41) and all other small parts (5, 29, 35, 36,

39)

Dismantling finished all the parts are present it is enough to

clean everything with the water and soap to remove all the residues

of black powder without forgetting of of all oil to the reassembly

Reassembly:

Proceed in reverse order. There is no difficulty if you follow

the reverse order except for the hammer spring which is very easy

to go up if you observe the following method well.

In order to engage the spring of the hammer under the hammer roller,

the hammer spring screw (20) must be unscrewed in part before

the under-guard (21) is put in place, the 2 rear sub-guard screws

And the hammer spring underneath the roller and firmly tighten

the hammer spring screw (20) which has the effect of bending the

spring. This is an exemplary simplicity, although it could be

difficult if the hammer spring were screwed completely before

putting the guard back in place.

When replacing the barrel, do not forget to put the hammer in

the half-cocked position, to lower the cam to stop the complete

insertion of the barrel on its axis.

As can be seen from the photographs with the years, the deposit

of the residues of powder to well marked the brass at the level

of the in custody, proof if it is necessary that the weapon must

be cleaned regularly, which the former owner of The weapon had

undoubtedly neglected.

PS; I could have used a new weapon to make more beautiful pictures

of this demonstration but the pedagogical part would not have

been conclusive because some people could have believed that it

was useless to disassemble all this for the maintenance, believing

that The black powder only dirty the barrel and the barrel, proof

here that the powder fouls everywhere.